Plastic Injection Moulding Manufacturer: Key Factors to Consider Before Partnering in 2025

The demand for high-quality, cost-effective, and timely plastic components is on the rise across industries such as automotive, consumer goods, medical devices, and packaging.

With the plastic injection moulding industry projected to reach $427.07 billion (INR 31.87 lakh crore) by 2029, technological advancements and innovations are reshaping how manufacturers deliver products.

This makes choosing the right plastic injection moulding manufacturer even more critical for ensuring quality, performance, and efficiency in your production process.

So, what are the key factors to consider? Let’s take a look:

14 Factors to Consider when Choosing a Plastic Injection Moulding Manufacturing Partner

Choosing the right plastic injection moulding manufacturer involves evaluating various key factors that ensure efficiency, quality, and reliability. Here are some important considerations to guide your decision:

- Industry Experience and Expertise

When evaluating potential plastic injection moulding manufacturers, the first factor to consider is their industry experience and expertise. An experienced manufacturer brings valuable knowledge to the table, which can help you navigate challenges in the design, production, and regulatory compliance phases.

- Customization and Design Support

One of the key benefits of injection molding is the ability to customize your designs. Before partnering with a manufacturer, evaluate their ability to support custom design requirements. A capable plastic injection moulding manufacturer should offer design services that help you create products that meet your specifications.

- Material Selection and Quality Control

Material selection plays a crucial role in the performance, durability, and cost of your final product. A wide range of materials, including thermoplastics, thermosets, elastomers, and bio-based materials, can be used in injection molding.

- Production Capacity

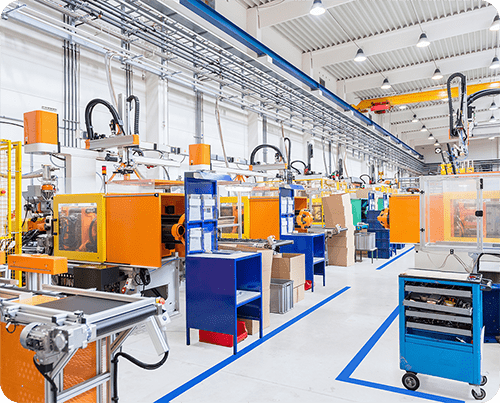

The production capacity of a plastic injection moulding manufacturer is a critical consideration, especially if you anticipate scaling production over time. Evaluate whether the manufacturer has the equipment, labor force, and infrastructure to meet your current and future production needs.

- Engineering Support

Engineering support is essential for ensuring that your product is manufactured efficiently and according to the required specifications. A plastic injection moulding manufacturer with in-house engineering capabilities can help optimize designs, resolve production issues, and reduce material waste.

- Sustainability Practices

Sustainability is becoming a key focus for businesses and manufacturers alike. In 2025, companies that prioritize sustainability in their operations are better positioned to meet regulatory requirements and also benefit from improved brand reputation and customer loyalty.

- Cost-Effectiveness and Value

While cost is a crucial factor in choosing a plastic injection moulding manufacturer, it’s important to focus on overall value rather than simply the lowest price. A manufacturer who offers competitive pricing but also prioritizes quality, timely delivery, and customer service can provide better long-term value for your business.

- Location and Logistics

The location of the plastic injection moulding manufacturer can significantly impact your lead times and shipping costs. If you need fast delivery times or have tight deadlines, choosing a manufacturer closer to your business operations may be a smart decision.

- Timely Project Completion

Meeting deadlines is essential for staying competitive in the market. When selecting a manufacturer, check their track record for timely project completion. Delays in production can cause ripple effects throughout your supply chain, leading to missed market opportunities.

- In-House Tooling and Equipment

Manufacturers with in-house tooling and equipment have more control over the production process, leading to faster lead times, better quality control, and reduced costs. Tooling is an essential part of injection molding, and having an in-house team that designs and maintains the molds can help reduce the time it takes to get products to market.

- Post-Production Services

Post-production services such as assembly, packaging, and testing can help streamline your operations and save you time. Some manufacturers offer additional services to ensure that your products are ready for shipment, including final inspections and packaging.

- Supply Chain Support

A strong supply chain is essential for ensuring consistent production and timely delivery. Choose a manufacturer with a reliable supply chain that can handle material sourcing, inventory management, and logistics.

- Customer Service

Good customer service is essential for maintaining a smooth working relationship with your manufacturer. Look for a manufacturer who is responsive to your needs, provides clear communication, and offers quick solutions to any issues that may arise during the production process.

- Certifications and Standards Compliance

Ensure that the plastic injection moulding manufacturer meets relevant industry standards and holds certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), and ISO 13485 (medical device manufacturing). These certifications demonstrate the manufacturer’s commitment to maintaining high-quality standards and complying with regulatory requirements.

Why JaiRaj Group is Your Ideal Plastic Injection Moulding Manufacturing Partner

With a commitment to sustainability, cutting-edge technology, and a customer-centric approach, JaiRaj Group offers a full range of services, including design support, engineering assistance, and post-production services.

- Customized Mobility Solutions: Specializes in durable, lightweight seating bases for e-bikes and compact EVs, supporting the growing mobility sector.

- Heavy Equipment Components: Manufactures rugged body panels and canopies for mining and construction vehicles, designed to withstand harsh environments.

- Defense-Grade Manufacturing: Provides military-grade polymer components for vehicles and UAVs, meeting stringent defense standards.

- Aerospace Expertise: Delivers lightweight, FST-compliant components like ducts and panels for the aerospace industry, ensuring flight safety.

- In-House R&D and Tooling: Utilizes in-house R&D and advanced tooling to optimize designs, reduce costs, and accelerate production timelines.

- Multi-Sector Expertise: Serves diverse sectors including railways, drones, and solar, providing reliable solutions across industries.

Final Words

Choosing the right plastic injection moulding manufacturer is a pivotal decision for your business. By considering factors such as industry experience, material selection, sustainability practices, and production capabilities, you can ensure a successful partnership that drives growth and success.

JaiRaj Group’s advanced manufacturing technologies and focus on sustainability make them a trusted partner for your plastic injection moulding needs. The in-house R&D, engineering support, and diverse product range ensure that every project is handled with precision and care.